Imperfection

Imperfection size limits

Illustration

Reasons

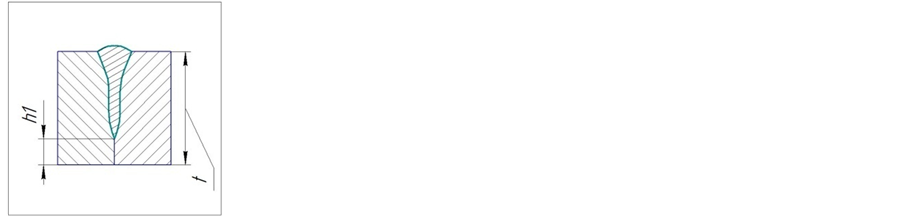

Incomplete penetration

Lack of penetration for full penetration welds.

Low laser power; Bad edge surface preparation

D.  ≤ 0.15 T max. 1 mm

≤ 0.15 T max. 1 mm

C. not permitted

B. not permitted

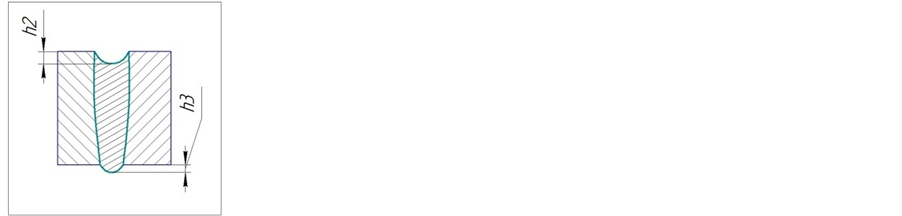

Incompletely filled groove & excessive penetration

D.  ≤ 0.15 T max. 2 mm

≤ 0.15 T max. 2 mm

C.  ≤ 0.1 T max. 1.5 mm

≤ 0.1 T max. 1.5 mm

B.  ≤ 0.05 T max. 1 mm

≤ 0.05 T max. 1 mm

High laser power; Low welding speed; Metallurgical instability during welding

D.  ≤ 0.2 + 0.3 T max. 5 mm

≤ 0.2 + 0.3 T max. 5 mm

C.  ≤ 0.2 + 0.2 T max. 5 mm

≤ 0.2 + 0.2 T max. 5 mm

B.  ≤ 0.2 + 0.15 T max. 5 mm

≤ 0.2 + 0.15 T max. 5 mm

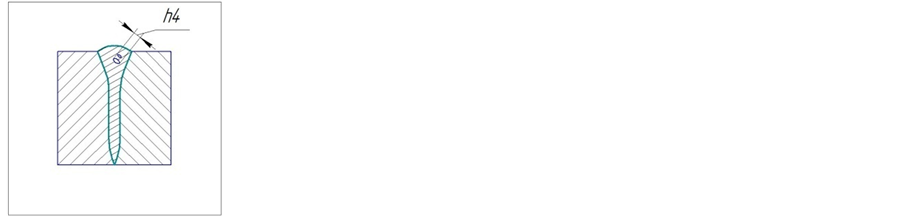

Porosity and gas pores

Maximum dimensions for a single pore.

Incomplete cleaning of the edge surface; High gas saturation of metal; High welding speed

D. 1 or  ≤ 0.5 T max. 5 mm

≤ 0.5 T max. 5 mm

C. 1 or  ≤ 0.4 T max. 3 mm

≤ 0.4 T max. 3 mm

B. 1 or  ≤ 0.3 T max. 2 mm

≤ 0.3 T max. 2 mm

Cracks

All types of cracks except micro cracks (less than 1 mm2 crack area)

High internal stress; High amount of diffusive hydrogen in the weld metal; Brittle structure in the HAZ

D. not permitted

C. not permitted

B. not permitted